Fully Open Top Window, Film Covered Venlo Type Multi Span Agriculture Greenhouse

Products Description

Suitable for large-area planting and can be equipped with a variety of modern intelligent equipment to adjust the indoor temperature and humidity to adapt to the growth environment of crops, thereby increasing crop yields.

For some flower plants that require relatively high air temperature in the environment, the multi-span greenhouse is more suitable for growing and increasing yield. The main body adopts a hot-dip galvanized frame, which improves the life span.

| span | 9.6m/10.8m/12m Customized |

| length | Customized |

| eaves height | 2.5m-7m |

| Wind Load | 0.5KN/㎡ |

| Snow Load | 0.35KN/㎡ |

| Max.discharge water ability | 120mm/h |

| Covering material | Roof-4,5.6,8,10mm single layer tempered glass |

| 4-side surrounding: 4m+9A+4,5+6A+5 hollow glass |

Frame Structure Materials

1. High -quality hot -dip galvanized steel structure, uses 20 years of service life.

2. All steel materials are assembled on the spot and do not require secondary treatment.

3. Galvanized connectors and fasteners are not easy to rust.

Covering Materials

PO/PE film covering Characteristic: Anti-dew and dustproof , Anti-dripping, anti-fog, anti-aging

Thickness: 80/100/120/130/140/150/200micro

Light transmission: >89% Diffusion:53%

Temperature range: -40C to 60C

Shading System

It is distinguished by the location of the greenhouse shading system. The shading system of greenhouse is divided into external shading system and internal shading system. The shading system in this case is to shade the strong light and reduce the intensity of light to achieve a suitable environment for plant production. At the same time, the shading system can reduce the temperature inside the greenhouse to a certain extent. The external shading system provides some protection to the greenhouse in areas where hail is present.

Depending on the preparation material of shade netting, it is divided into round wire shade netting and flat wire shade netting. They have a shading rate of 10%-99%, or are customized.

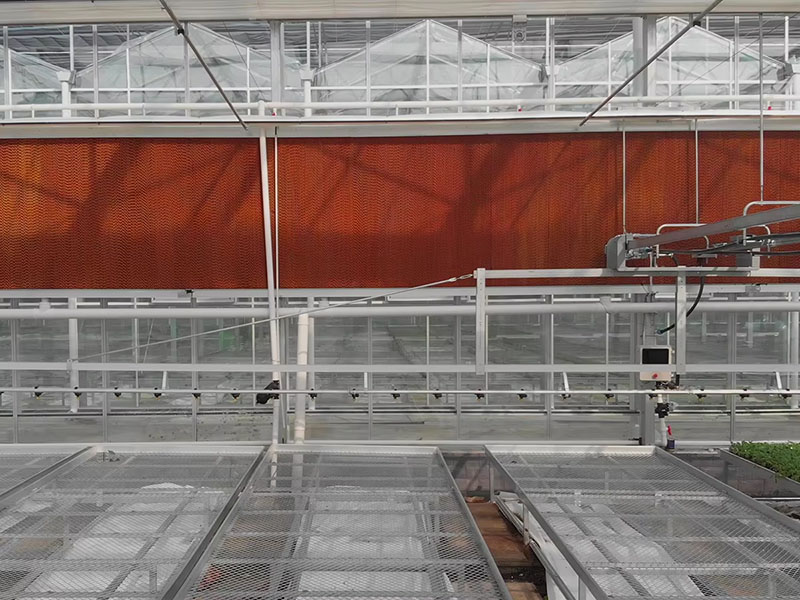

Cooling System

Depending on the environment of the greenhouse location and the needs of the customer. We can use air conditioners or fan & cooling pad to cool the greenhouse. Generally speaking, from the aspect of economy. We usually use a fan and a cooling pad together as a cooling system for the greenhouse. The cooling effect is determined by the temperature of the local water source. In the water source greenhouse about 20 degrees, the internal temperature of the greenhouse can be reduced to about 25 degrees. Fan and cooling pad is an economical and practical cooling system. In combination with the circulating fan, it can reduce the temperature inside the greenhouse faster. At the same time, it can accelerate the air circulation inside the greenhouse.

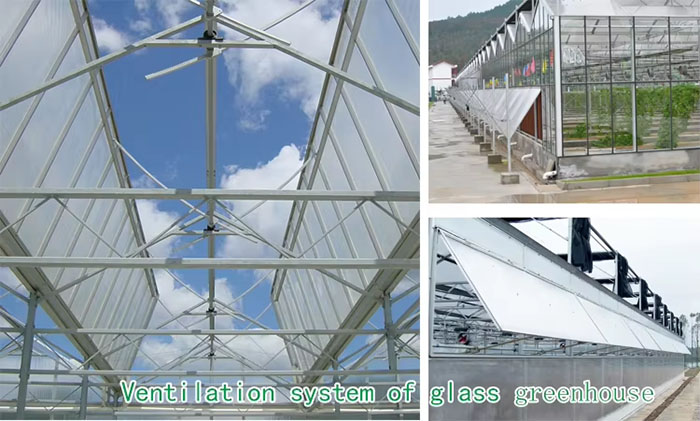

Ventilation System

According to the location of ventilation, the ventilation system of greenhouse is divided into, top ventilation and side ventilation. According to the different ways of opening windows, it is divided into rolled film ventilation and open window ventilation.

The temperature difference or wind pressure inside and outside the greenhouse is used to achieve air convection inside and outside the greenhouse to reduce the temperature and humidity inside.

The Exhaust Fan in the cooling system can be used for forced ventilation here.

According to the customer's demand, insect-proof net can be installed at the vent to prevent the entry of insects and birds.

Lighting System

The greenhouse's supplemental light system has several advantages. Suppressing short-day plants; promoting flowering of long-day plants. In addition, more light can extend the time of photosynthesis and accelerate plant growth. At the same time, the light position can be adjusted to achieve a better photosynthesis effect for the plant as a whole. In cold environments, supplemental lighting can increase the temperature in the greenhouse to a certain extent.

Greenhouse Bench system System

The bench system of the greenhouse can be divided into rolling bench and fixed bench. The difference between them is whether there is a rotating pipe so that the seedbed table can move left and right. When using the rolling bench, it can better save the indoor space of the greenhouse and achieve a larger planting area, and its cost will increase accordingly. The hydroponic bench are equipped with an irrigation system that floods the crops in the beds. Or use a wire bench, which can greatly reduce the cost.

| Length | customized according to your requests |

| Width | 1.2m;1.5m ;1.7m, or customized |

| Height | 0.7m , height adjustable 8-10cm |

| Mesh size | 120×25mm,30x130mm,50×50mm |

| Capacity | 50kg/m2 |

| Material | Galvanized+electrostatic spray,Stainless steel bright wire |

| components | wheel, Frame, screws ...etc |

Mesh wire

Galvanized steel, excellent anti-corrosion performance

Outside frame

Aluminum alloy frame, anti-radiation, anti-rust, strong and durable

Heating System

There are various types of greenhouse heating equipment commonly used nowadays. For example, coal-fired boilers, biomass boilers, hot air furnaces, oil and gas boilers and electric heating. Each equipment has its own advantages and its limitations.